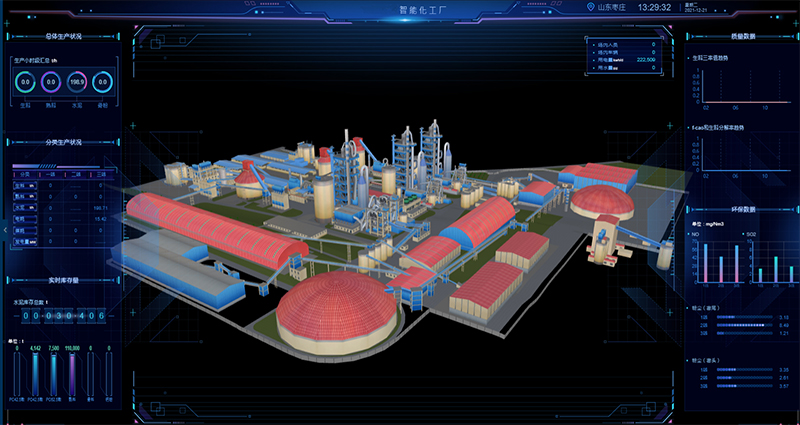

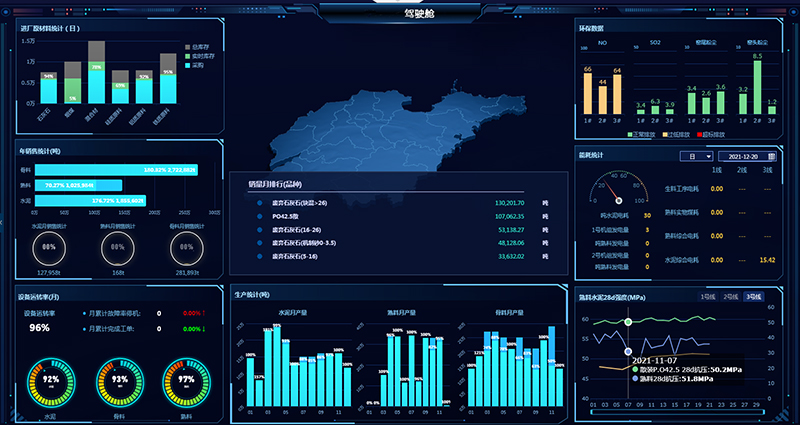

Position:Main business > Smart O&M Services

Position:Main business > Smart O&M Services  Smart O&M Services

Smart O&M Services With the aging of equipment year by year, the age of maintenance personnel is becoming younger and the deficiency of technical strength reserve, the cost and the time that the factory spends on operation and maintenance present an increasing trend.

With German industry 4.0 as the benchmark, and with the help of smart digital tools, the concept of smart repair and maintenance aims to quantizes, formulizes and visualizes daily maintenance, utilizes data to drive decision-making and thus forms a closed loop of repair and maintenance. And improve maintenance procedures, enhance personnel's comprehensive quality, regularize safety and production system, achieve reliable and predictive repair and maintenance, promote safety and stability of equipment operation, extend equipment's life cycle and thus improve production efficiency, by maintaining changes of the management concept and establishment of the system.